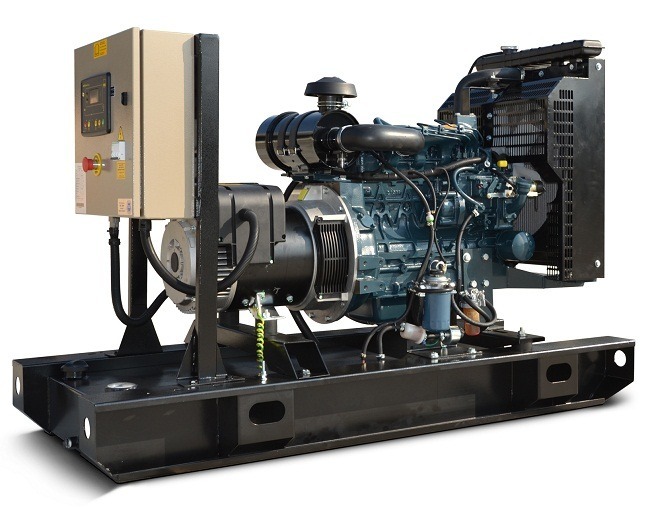

Kubota Diesel Generator

23kVA Prime – 25kVA Standby

Kubota Diesel Generators:

Kubota Engine is a reliable robust engine with a low cost of ownership. Kubota Produces engines with the highest standards of Japanese technology, having its own casting facility and technology securing a consistent production of complex designed crankcases to maintain unbeatable quality of the engines. It provides consistent reliable quality, design diversity for multiple solutions, multiple emission levels.

Genset Model KT23:

3Phases, 60Hz,220v/380v, 1800rpm

Standby power: 25 kVA / 20 kW.

Prime power: 23 kVA / 18.4 kW.

Includes:

Engine: Kubota, V2203-E2-BG, 4 Cylinders (Japan Origin)

Alternator: Leroy Somer (EU Origin)

Controlled by: DSE Control Panel (UK Origin)

Soundproof Canopy, Daily tank, Batteries, Emergency Push Button.

Benefits and Features

- Diesel-Powered Generator

- Fuel Efficient Generator

- Reliable Power Generator

- Low Maintenance Generator

NOTES:

- The applicable voltage range is 220V, 380V to 400V for 60Hz applications. For other voltages, please consult factory.

- This generating set is of fixed speed of 1800 rpm.

- KT23 is the prime power rating of the generating set is where a variable load and unlimited hour usage are applied with an average load factor of 80% of the prime rating over each 24-hour period. Noting that a 10% overload is permitted for 1 hour in every 12-hour operation.

- KT25S is the standby power rating of the generating set is where a variable load limited to an annual usage up to 500 hours is applied, with 300 hours of which may be continuous running. Noting that no overload is permitted.

Technical Specifications

- 3-Phase Generator

- 60Hz Generator

- 220v/380v Generator

- 1800rpm Generator

Applications in Saudi Arabia

- Backup Power Generator

- Industrial Generator

- Commercial Generator

- Residential Generator

Location-Based

Reliable Kubota Generators 23kVA in Saudi Arabia | Power Solutions for Riyadh, Jeddah, Dammam and Beyond

Kubota V2203 Series Engine Maintenance Genuine Parts Numbers

| Fuel Filter | HH166-43560 | |

| Oil Filter | HH164-32430 | |

| Air Filter outer | 15606-11080 |

| Fuel Element | 1G311-43380 | |

| Fan Belt | 15469-97010 | |